High-performance ceramic for oxygen measurements

Kyocera’s subsidiary, Kyocera Fineceramics Solutions GmbH, formerly part of Friatec GmbH, develops robust oxygen sensors for managing combustion in industrial processes.

- Fine Ceramic Components

Kyoto/London - The ceramics division of Friatec GmbH, which was integrated into Kyocera Fineceramics Solutions GmbH after the acquisition, is known for its high-performance ceramic components for a wide application range. With DEGUSSIT FZY, it has an innovative material at its disposal for measuring oxygen at high temperatures. Leading manufacturers of gas analysers and measurement systems such as Zirox Sensoren und Elektronik GmbH have relied on the quality of this technology for many years.

Precise measurement of oxygen content

It is essential to know the level of oxygen of a gas or be able to prove its presence in various industrial processes. Measuring the level of oxygen at high temperatures and under difficult conditions, such as when subject to chemical or mechanical influences, is only possible by utilising so-called solid-state electrolytes. One such material, DEGUSSIT FZY, a ceramic solid-state electrolyte comprising an yttria partially-stabilised zirconia, particularly stands out due to its resistance to temperature changes and corrosion. It can be used at temperatures up to 1,500 °C. Depending on the heating of the sensors, they can be installed directly into the high-temperature process or even outside of this process. Response times are also very short with a constant measurement signal.

Wide application range regarding industrial processes

Due to the material’s durability, sensors with DEGUSSIT FZY are particularly suitable for managing combustion processes, such as those commonly found in gas-fired industrial ovens, combustion engines, and power stations. In order to ensure a smooth operation and an efficient use of resources in these processes, the air or level of oxygen must be precisely configured. The applications of sensors with DEGUSSIT FZY therefore range from annealing processes to shielding gas monitoring and surface treatments (hardening plants) to Redox reactions and diffusion processes. The product is also used in biotechnical processes as well as for controlling food packaging. One prerequisite for the various possible uses is the variety of products in which oxygen sensors are available: products made of DEGUSSIT FZY include single-ended or double-ended tubes, sheets, crucibles, H-sleeves, spheres, and moulded parts.

How the solid-state electrolyte sensors work

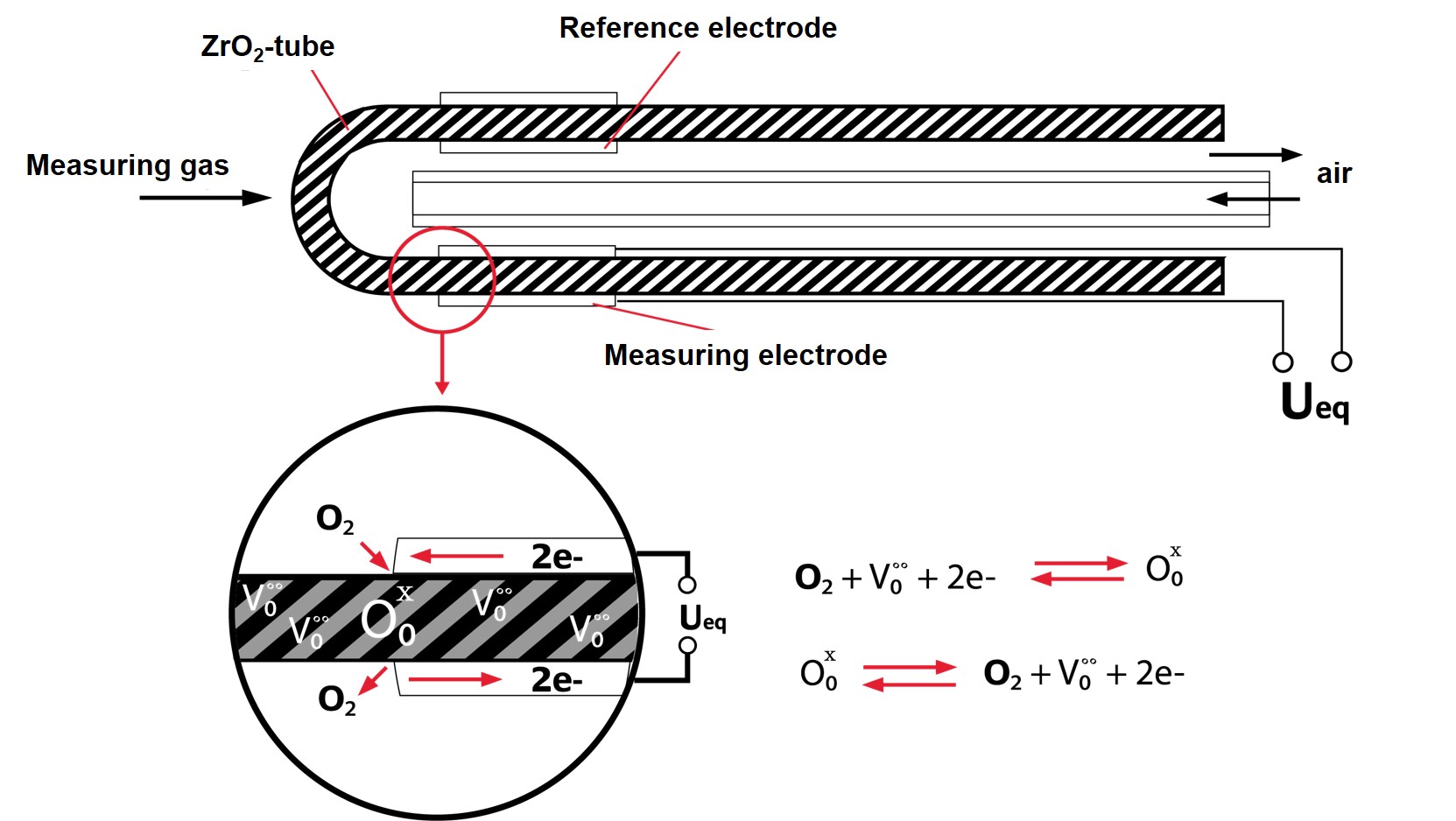

Yttria (Y203) partially-stabilised zirconia is a conductor of oxygen ions at temperatures above 600 °C. Solid-state electrolyte sensors with FRIALIT®-DEGUSSIT® ceramic make use of this property. The zirconia ceramic acts as a gas-proof separating layer between two gases with differing oxygen concentrations. Various chemical potentials arise when electron conductors are on both sides, as is the case with a layer of platinum, for example. As a result, the electrical tension between the two electrodes can be measured. The tension depends on the difference in the oxygen concentration of both gases. Air is often used as a reference gas.

About Zirox Sensoren und Elektronik GmbH

Zirox is a medium-sized company based in Greifswald, which was founded in 1989 and is now one of the leading manufacturers of gas analysers and measurement systems, offering around 750 product variants as well as custom solutions and products. The company develops and manufactures its products exclusively in Germany and has relied for a number of years on the quality of the DEGUSSIT FZY tubes produced by Kyocera Fineceramics Solutions GmbH. Zirox has established an international presence with its technologies and is particularly active on the Asian market.